|

1964 LANCIA FLAVIA CONVERTIBLE RESTORATION

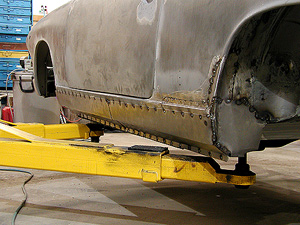

This Flavia convertible was brought to us by a client who had seen another that we had restored a few years prior. I was really not too sure about the project to begin with as it was possibly the worst rusted car I’d ever considered restoring. After removing the paint and the flat sheet metal bottom that was wood screwed in place, we had a car that was close to breaking in half.

The amazing part was everything from the rocker panels up was in very good condition.

The client bought the car off of an Ebay ad sight unseen, a “barn find”. The ad represented the car as having no rust. I’m guessing they never bent over and looked underneath.

After we brought the car back from media blasting the bare shell, I showed it to my client. He is a man of sterner stuff than most, who had the vision of a finished car that none of the rest of us saw, and I have a pretty good imagination having owned several of these cars over the years and having restored several as well. He told us to press on.

Once it was decided that we would do the restoration, we removed the remaining rusty metal and welded braces across the doors before removing them to make sure the car stayed “square” with the world.

Over the next few months, we made the inner rocker panels, center structural panels and outer panels, slowly returning to the car some of its basic strength in the main body. With that done, we installed new floor panels the client found in Europe. I remade the structural areas to which the front sub frame bolts, along with the rear frame section that attaches to the leaf springs to support the rear axle. We had to make many areas of the interior, the trunk floor and part of the door bottoms from scratch.

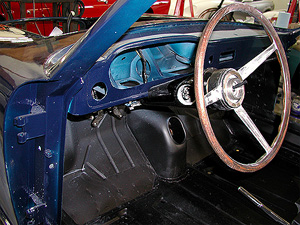

Once all the metal work was finished, we rolled the car into the paint booth and flooded the interior, exterior and box sections of the car with PPG DP90 self-etching black primer. Then we began sorting out the body work and panel fit so the car could be painted.

When we painted the car, we refinished it in Lancia Blue using a urethane base coat clear coat paint system from PPG.

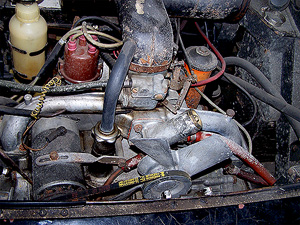

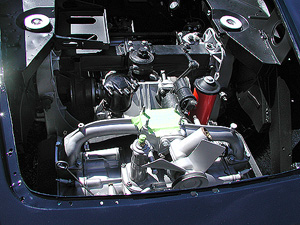

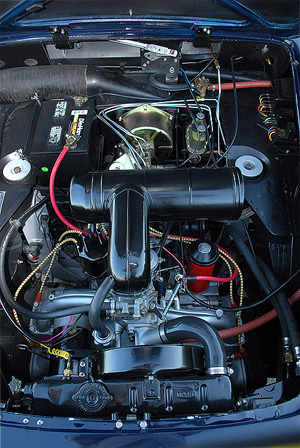

In the meantime we had the engine and gear box rebuilt by another shop the client had used before for other cars in his collection.

We went through brakes, made all new brake lines (no small task on a Lancia with a remote brake booster), rebuilt and restored the suspension, replaced wheel bearings on all four corners and began reassembling the car.

When the engine and gear box returned, they were detailed and fitted to the front subframe and installed in the car.

The car was ready for all the trim, lights, chrome and glass, whereupon it was delivered by truck to the client, who proceeded to install a new wiring harness he found Europe. It came back to us upholstered so we could fine tune the electrical system and sort out the mechanicals.

In the end, what came in as a rusty piece suitable for the scrap yard was once again a lovely show condition classic.